Interior finishes for the healthcare environment not only look different from corporate or hospitality finishes, but they perform differently as well. Selecting healthcare finishes involves much more than simply choosing contemporary over traditional design or incorporating the latest color or pattern trends.

Well thought-out interior design choices can make a difference in public perception, can positively impact the environment and as recent studies have shown, have a powerful and positive effect on patient healing.

Selecting finishes is not merely a choice between aesthetics and affordability. Array’s design professionals also consider appropriateness, maintainability, life-cycle costs and environmental impacts. Additional considerations such as patient psychological needs, marketing/image of the hospital and staff recruitment and retention influence Array’s design choices.

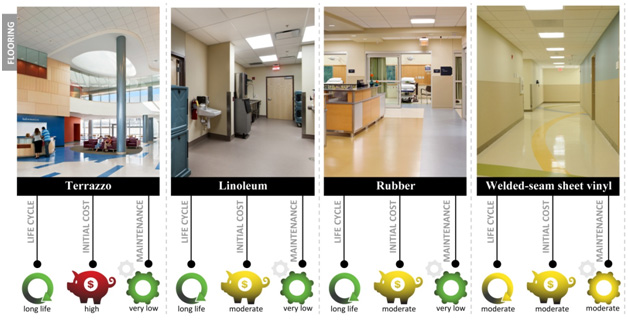

Flooring

The interior surface which often receives the most attention in the healthcare environment is flooring. What is also equally deserving of this attention is the wide variety of available flooring types. They include the following options:

• Terrazzo

• Linoleum

• Rubber

• Homogeneous Sheet Vinyl (Heat welded)

• Porcelain Tile

• Luxury Vinyl Tile

• Carpet (Broadroom and Tile)

• Vinyl Composition Tile

Considerations in healthcare flooring include environmental issues, infection control, air quality and patient & worker safety, as well as comfort, acoustics and aesthetics. Health Care Without Harm has published a fact sheet that documents reasons to avoid PVC vinyl flooring including associations with asthma, the release of highly toxic dioxins and reproductive toxicants. Alternative (non-PVC) flooring options include rubber and linoleum flooring.

Wall Surfaces

Though the available wall surfaces are not as numerous as the choices in flooring, they continue to expand far beyond the institutional look of the past. The major choices include the following:

• High-performance coatings – High-performance wall coatings are perfectly appropriate for healthcare facilities. In many cases, they are water-based polyurethane products, some with antimicrobial protection, that are up to 10 times more durable than standard acrylic latex paint.

• High Performance Vinyl Wall Coverings – Manufacturers are working to develop lighter-weight non-polyvinyl chloride products, incorporate recycled content into their products, micro-perforate their products to ease wall moisture entrapment concerns and lower the volatile organic compounds (VOCs) emitted into the interior environment.

• Textile Wall Coverings – Textile wall coverings provide an upscale and warmer environment. They are commonly developed with natural materials, such as linen, grass cloth, silk, jute and cork or synthetic materials such as poly olefins.

• Paint – The improvement in water-based paints has been a huge step forward for the healthcare industry and its interior environment. More recently, the reduction in VOCs has made paint an even better solution for healthcare facilities.

Upholstery Options

Manufacturers have put much work into developing new and improved upholstery for rugged applications like healthcare. Choices available to health facilities professionals include the following:

• High-performance textiles– Many textile companies are adding a variety of upholstery design options which suit the varying requirements of the healthcare environment. For instance, upholstery in an emergency department waiting area would most likely need an easily cleaned surface, a guest chair in a lobby may not.

• Vinyl textiles – Like vinyl wall covering, vinyl textiles have developed quickly over the past few years. The look and feel of vinyl textiles has moved to a much more appealing textile-like material. There are linen looks, much-improved leather looks and printed & embossed patterns. There are even options for non-PVC vinyl textiles.

• Standard textiles – Standard textiles are still needed and used in healthcare environments. However, the fiber content and testing should be reviewed: some resist stretching and pulling over time, while others may have a tendency to nap or have color-fastness issues. Additionally, some textiles are more suited for lower to moderate use, while others are virtually indestructible in a 24/7 environment. When selecting the textile, the review of double rubs is very important. At Array we will not specify anything under 50,000 double rubs.

Hard Surfaces

Materials used for counters, shelving, millwork, accents and other hard surfaces have also evolved over the years. Following are some of the major choices:

• Natural stone – Natural materials such as granite, marble, limestone and glass are great ways to provide a visual punch. They can be used as part of built-in millwork elements, feature walls or floor accents.

• Solid surface materials – In addition to the traditional wood-look, plastic laminate palettes have grown to include metal-look, embossed, patterns, abstracts, fibers, etc. Solid surface materials provide wonderful attributes when installed as seamless horizontal and vertical surfaces, shower walls, integral sinks and backsplashes when used as wall protection (corner guards and bumper guards).

• Plastic laminates – In addition to the traditional wood-look, plastic laminate palettes have grown to include metal-looks, embossed patterns, abstract fibers, etc. The use of laminate is limited to vertical surfaces. At Array, we prefer not to use laminate on countertops because of the exposed edges and tendency to chip. The use of laminate on a vertical surface is a great alternate to more expensive options such as veneer or solid phenolic panels. Wherever there is an exposed edge or corner, it is reinforced with a harder material such as metal or solid surface.

Jolene Mudri, previously with Array Architects