The value that BIM can create for project delivery teams and building owners has been the subject of many detailed studies, well written articles and reports over the past few years. Most detail the key advantages of Building Information Modeling (BIM) as being improved decision making and reduction in costly field changes that result from the development of detailed information and analysis achieved much earlier in the building process. While these benefits represent the low hanging fruit, there are many other opportunities, often ignored by project teams, to provide significant additional value. Increases in cost of healthcare construction combined with the complexity inherent in healthcare projects present an opportunity for project teams to deliver enhanced value to the owner throughout the life cycle of the building.

While there is increasing momentum in the A/E/C industry to adopt BIM practices, there is a wide variety of its usage by project teams. All too often, decisions surrounding the use of BIM on projects center on what is most efficient and most economical for the AEC project delivery team with little regard to providing the enhanced value for the entire life cycle of the project. Because the level of development of models currently being delivered on projects varies widely, many owners are perplexed and sometimes skeptical about what they should be expecting and requiring from their project teams. BIM should not be used simply for the automation of drawing production, but to:

• Provide a higher degree of cost certainty

• Reduce risk during construction

• Identify opportunities for prefabrication

• Facilitate building operations and maintenance

So how does an owner ensure that its AEC team will utilize BIM to maximize value for the entire life cycle of the building rather than just the design and construction phase? How does the owner ensure that it will receive a digital asset at the completion of the construction phase that can assist in the facility maintenance process? By planning how BIM will be utilized throughout the four phases of the building lifecycle; Plan, Design, Construct and Operate, the owner can maximize the value received from the process. Recognizing that BIM is a process and not a deliverable is important in achieving this enhanced value. It is the BIM planning process that I will focus on in this two part series.

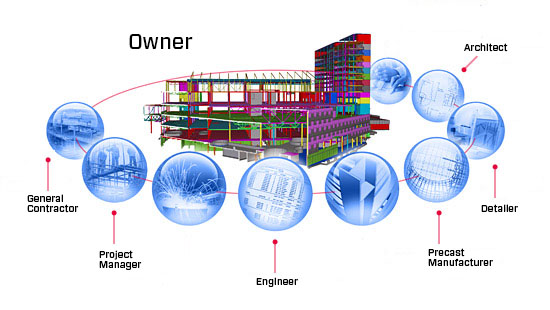

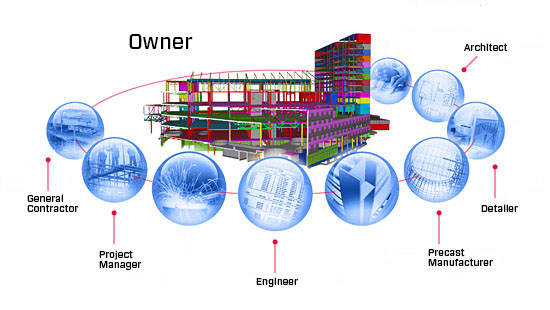

To capture the most value from the BIM process, the designer should initiate collaboration with the team early in the process. This collaboration should occur prior to models being created. Opportunities to collaborate with the entire team, including facility managers, users, contractors, consultants, engineers and suppliers must be explored at the earliest stages of the project. By investigating possible downstream value, defining as a team how the model will be used in the design, fabrication, construction and facility maintenance processes, maximizes value for both the project and the design/construction team. This collaboration process results in a BIM Execution Plan (BEP) that provides a framework for the project team to deploy BIM technologies and best practices. This plan delineates roles and responsibilities of each team member, the detail and scope of information to be shared, relevant business processes and supporting software.

While there are certain levels of integration implied by the BEP, the actual methods of integrating a design team are not. By participating in the development of the BEP, the project team is acknowledging the importance of delivering services in an integrated environment and is committing to working in as integrated a manner as the contract process (CM at Risk, Design / Bid / Build or Design / Build) will allow. The process results in the project team striving to achieve higher levels of integration within the design and construction process than traditional methods of design have historically produced. One of the principal objectives of incorporating BIM in any project, regardless of the size or duration, should be to improve both the quality of design solutions and the exchange of information between the parties. The models and analyses called for in the BEP are used to support the decision making process for high performance healthcare building design and requires cooperation between the design team, the contractors and the owner. The BEP that results from this process should be used as a contract exhibit for the AEC team.

Array has successfully used a four step procedure, modeled after the Penn State buildingSMART alliance research project, to develop a detailed BEP. It is designed to steer owners, program managers and early project participants through a structured process to develop detailed, consistent plans for a project. The four steps, each of which is a separate meeting, consist of:

• Identifying the appropriate BIM goals and uses on the project,

• Designing the BIM workflows

• Defining the BIM deliverables

• Identifying the supporting infrastructure to successfully implement the plan.

The development of the BIM Plan is a collaborative process. Some portions of the procedure, e.g. discussing the overall project goals, are very collaborative tasks, while other portions, e.g. defining the required file structure or a detailed information exchange, do not necessarily require collaborative tasks. In the next article I will cover the four meetings and the work tasks that take place to advance the BEP in each of the meetings.

See Carl’s article featured on Healthcare Design Magazine’s blog here.