Technology within the textile industry continues to change dramatically. Since the early 1990s and the introduction of Crypton, there has been an influx of new products being brought to market for commercial upholstery. Many of these innovations claim to be environmentally friendly, more durable and more cleanable. In an effort to break down the mystery behind many of the technologies pros and cons, I will dive a little deeper into a few of the most prevalent options that are available.

Greenshield

Greenshield is Nanotechnology that attaches tiny nanoparticles to fabric to help create moisture and stain resistance. There are mixed environmental ratings: some cradle to cradle certifications, and some low indoor air emission ratings. This process is said to use 7‐10 times less the amount of fluorocarbons as similar fabric finishing in the industry. This finish is chemically bonded to any fabric that can withstand 250 degrees Fahrenheit washing, and is said to last the life of the fabric.

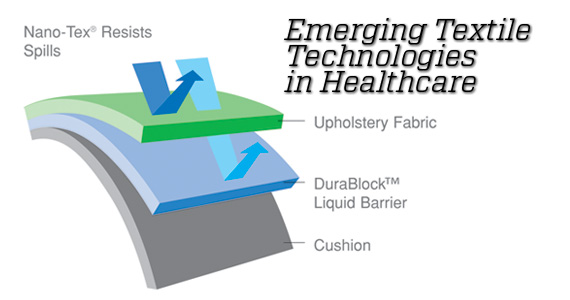

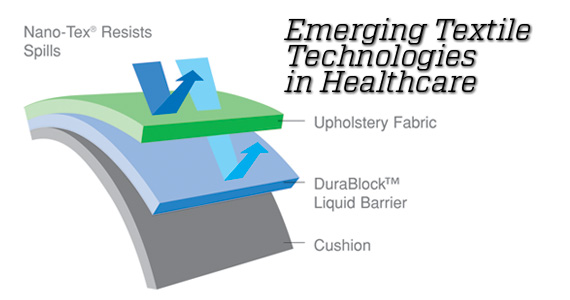

Nano-Tex

Nano-Tex is said to create permanent spill and stain resistance into product while improving abrasion resistance on any fabrics that it is applied to. It can also be combined with Dura-Block to make a liquid barrier on the back of the fabric and BioAM to create an antimicrobial fabric. It is not 100% chemical-free, but it is expected to be so in the future. The application of Nano-Tex does not affect the recyclability of fabric. This finish is chemically bonded to fabric and is said to last the life of the fabric.

Dura-Block

When used with Nano-Tex, Dura-Block creates a breathable liquid barrier on fabric that repels liquids and stains. It typically enhances the fabric’s abrasion resistance by 50%, contains no formaldehyde, Perfluorooctanoic acid (PFOA) or Volatile Organic Compounds (VOCs) and is 100% recyclable. The one caveat with Dura-Block treated fabrics is that the backing should not be laundered – only spot cleaned.

BioAM

BioAM is a non‐leaching antimicrobial treatment for Nanotex fabric that reduces odors and stains created by microbes through an electronic charge. BioAM is durable throughout the life of the product, and tested up to 50 healthcare-grade washings. It contains no arsenic, tin, heavy metals or silver and does not affect the recyclability of the fabric.

EnviroCoat

EnviroCoat is a 100% Polyester back coating for fabric and is intended to replace Acrylic and Latex backings and is 100% recyclable. This product is laminated to the back of a fabric, creating a fabric that repels liquids and stains. Despite the lamination, the fabric is still breathable and will last the life of the fabric while improving both abrasion resistance and seam strength of fabrics.

Crypton

Crypton is an integrated moisture barrier applied to fabrics that permanently transforms the fibers of the product. The backing is said to never separate from the face fabric and only fabrics that have been pre‐tested and approved can be made into Crypton. It is low in VOCs and is PFOA free. There is a five year warranty on the moisture barrier portion of Crypton.

InCase

InCase is a Customizable technology applied to fabric depending on use and is part of the Crypton family of products. It alters the molecular make‐up of fabric to increase the surface tension on a fabric and does not require stain and microbial‐resistant treatment. Almost any fabric can be treated with InCase, but its suggested uses are for cubicle curtains, panel fabric and bedding. InCase is said to last the life of the fabric, featuring silver Ion microbial protection, which resists both oil and water-based stains and does not utilize PFOA or Perfluorooctane sulfonate (PFOS).

Observations:

- Just because a product states it is low-VOC does not mean it does not off-gas – it will at some level.

- Silver is very toxic to both fresh and saltwater organisms. Silver will leach off of the fabrics it is used on and will release into the water stream when laundered. Not all silver technology is applied; some is woven into the fiber itself. The woven fabric has proven to leach less silver into the water stream.

- Products that use Fluorocarbons are contributing to greenhouse gases in our environment.

- Polyester is a petroleum-based product, but very rarely is polyester today completely virgin-made fiber. It is either partially recycled or 100% recycled. This makes it have one of the smaller footprints of most synthetic or natural fibers.

- Some manufacturers are looking to natural fibers such as cotton, wool and hemp in place of manmade fiber to create beautiful and durable products. Camira is one such manufacturer. Some of the technologies mentioned above can be used on these natural fibers to help their durability.

- Nano-Tex is now available through most manufacturers and can be custom applied to most commercial upholstery. Johns Hopkins Medical Center, after many mock-ups, standardized to only use fabric with a Nano-Tex Finish in their new Children’s and Adult Hospital.

- Furniture manufacturers today usually offer moisture barriers on their upholstered furniture pieces and therefore a second moisture barrier on the fabric would be redundant. Perhaps we have asked our fabric to do too many tasks in the past and as we move forward with environmental goals in mind, maybe our fabric can be a very durable covering that is aesthetically pleasing.

References:

www.greenshieldfinish.com

www.buildinggreen.com

www.greenspec.com

www.nohar.org

www.sustainablehospitals.org

www.healthierhospitals.org

www.greensource.construction.com

www.cryptonfabric.com; www.protectbeauty.com

www.knolltextiles.com;

www.environmentalhealthnews.org

www.cfstinson.com

www.greensource.construction.com

www.agion.com

Click here for a link to the Sustainable Action Leadership blog